What Tools Does A Mechanic Use

Mechanical engineers use these tools to safely transfer and process semiconductor articles such as circuit wafers flat panel displays and data disks.

What tools does a mechanic use. Mechanics also use shop tools such as drill presses and other large machines that must remain centrally located in a shop or hangar. Civilian mechanics are generally required to own their own tools for basic maintenance. So now that we have the basic mechanical tools and equipment sorted out lets try to understand what the mechanical domain is all about.

DeWalt a brand known for its heavy-duty power tools is now making sockets and wrenches as well. Semiconductor process systems include spin coaters wafer bonding systems and wire bonders. These are mechanical tools such as drills hand cutters and dremels.

More items you might want to add to a tool list for diesel mechanics include. Nanotechnology biotechnology composites computational fluid dynamics CFD and acoustical engineering have all expanded the mechanical engineering toolbox. Also mechanical engineers can test for and fix problems with this tool during the fabrication process.

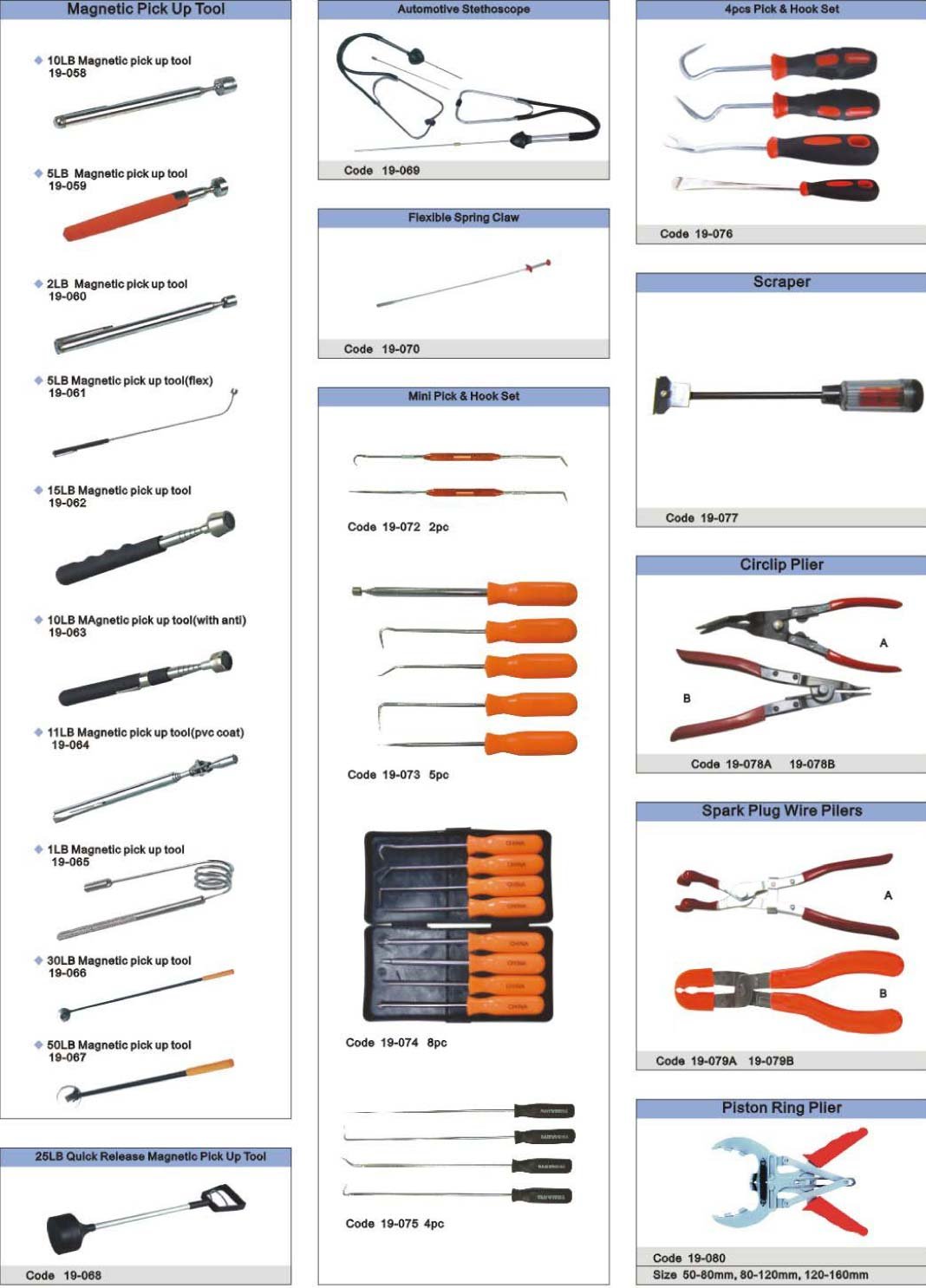

You use this to restore the body of the car. Some of these mechanics may specialize in a particular area or system of the vehicle such as a brake technician transmission rebuilder or automotive air-conditioning technician. Much like a doctors stethoscope a mechanics stethoscope is an acoustic device used to listen to internal sounds.

They are rarely required and can always be borrowed from your local mechanic. This tool might also include a sharp tool for piercing sheet metal a pair of mini. Wrenches aid in removing nuts and bolts.

Breakthroughs in materials and analytical tools have opened new frontiers for mechanical engineers. Mechanical and digital micrometers are commonly used in mechanical engineering applications and a specialized digital brake micrometer for automobiles has also been developed. Battery terminal clamp puller.