How To Start A Cnc Machine Business

For a shop that has just 500000 in annual work that generates a profit of 50000 to 75000 on top of the business.

How to start a cnc machine business. It is worth remembering that you do not just have to buy a brand new kit but can save money without making compromises on performance or functionality if you look to the used machinery market. Rocket Machining Design a customer of MSC may be a new kid on the block but it has learned a lifetime of lessons and wisdom in its early incarnationwith plenty of precision automotive and medical device parts and prototype business to boot. Most successful Profitable CNC Business Ideas businesses operate on a 10 to 15 percent net profit margin.

Ad Preview This Title Now for Free. Learn about the day-to-day activities of a CNC Machining Business owner the typical target market growth potential startup costs legal considerations and more. Manning Offers the Highest Value in ProgrammingDevelopment Books from World Class Authors.

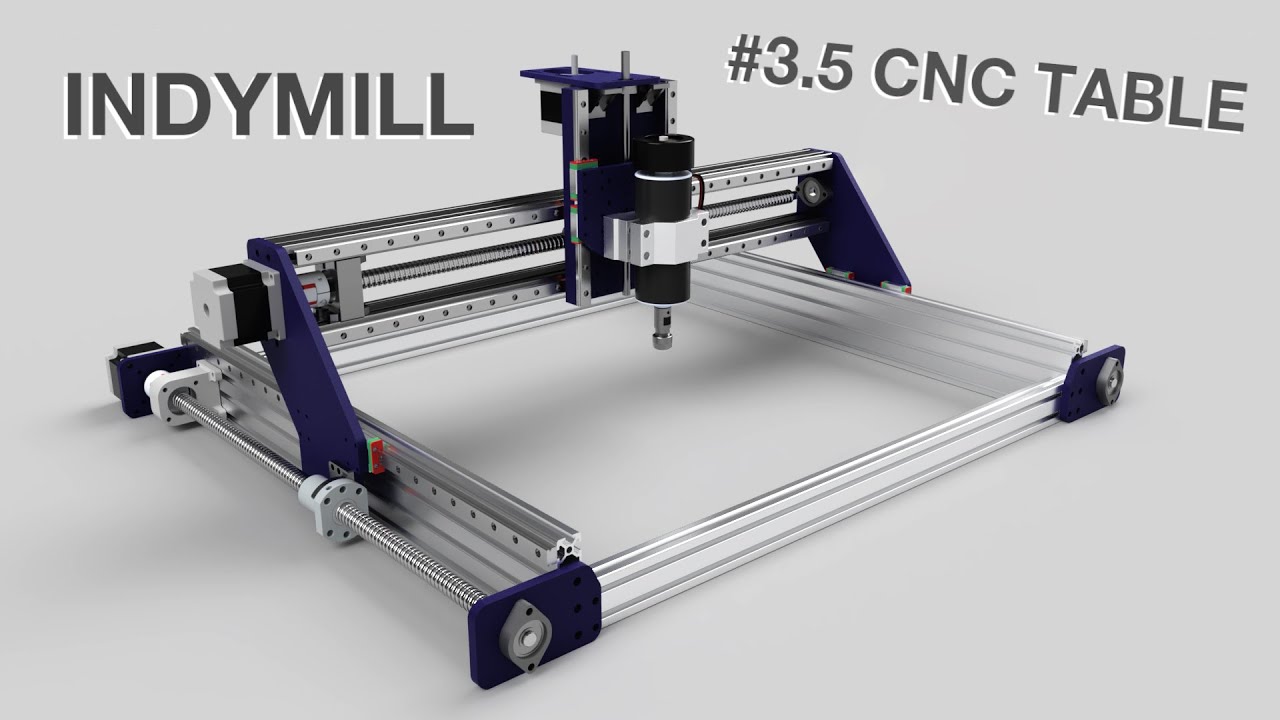

A CNC machining business will be in need of the right equipment to provide services to clients so this must be a priority to consider when you are getting started. Print or eBook Available. The main requirements for succeeding in this type of manufacturing business is to have a well-equipped workshop design and construction experience and good marketing skills.

Realign and strategically apply your resources to position your business for growth. First test the market and your team by starting small. Looking to start your own CNC business.

Profitable CNC Business Ideas to Make Money in 2020 Read this first So you own your own CNC machine. The limits on what can be done with a given machine now depends not only on the operator and the materials involved but also on the machine. Manning Offers the Highest Value in ProgrammingDevelopment Books from World Class Authors.

Start small Once you have your business plan and everything under control start small. Ad Assess new business opportunities and transform your idea into a viable venture. He sends his Easel files to X-Carve for carving letting the CNC machine carve while he works on other projects in his shop.