How To Sharpen Carbide Tipped Lathe Tools

My experience started with a high speed grinding wheel and over time I have moved to a moving belt system.

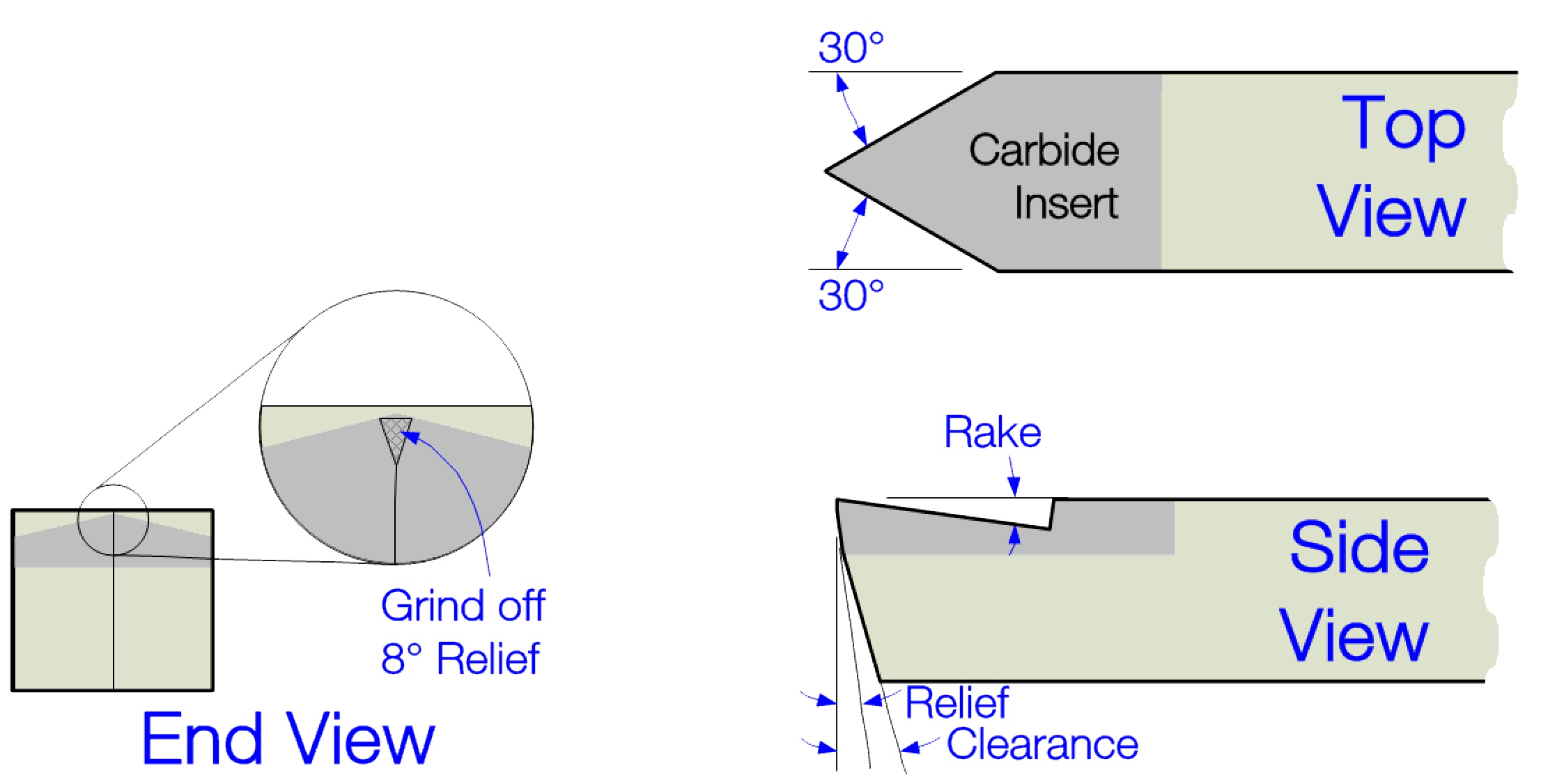

How to sharpen carbide tipped lathe tools. In either instance its important to relieve the shank such that only carbide is ground with the diamond wheel. It is a sled which rides atop the SVD-110 Tool. Waist with two elbows to reduce the shaking of the lathe tool sharpening.

Carbide tools can be sharpened on an ordinary bench grinder but it does not do the best job in terms of finish. In this video I explore different aspects a slow speed grinding. It takes practice to sharpen tools no matter what system you choose.

When grinding the turning tool should be placed in the horizontal center of the grinding wheel and the tip of the tool should be slightly upward for about 3 8 When the turning tool contacts the grinding wheel it should move horizontally in the left and right directions. Building your own carbide tipped lathe tools will bring much satisfaction fast and clean cuttingnot to worry about sharpening because you can just get a new carbide insert for 5 to 10 bucks. They had several grinders for carbide tools some with face type wheels and one like an ordinary bench grinder with 7.

Hold your tungsten carbide tool against the rest beneath the wheel. Be sure to have some lapping fluid on hand to use as a lubricant. During sharpening lathe tool please place the lathe tool on the horizontal center of the grinding wheel and the tip of the lathe tool is slightly upward about 3-8 when the lathe tool touches the grinding wheel that the lathe tool should be moved around horizontally.

How to use a slow speed grinder to sharpen carbide tooling. I talk about some techniques I u. Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup.

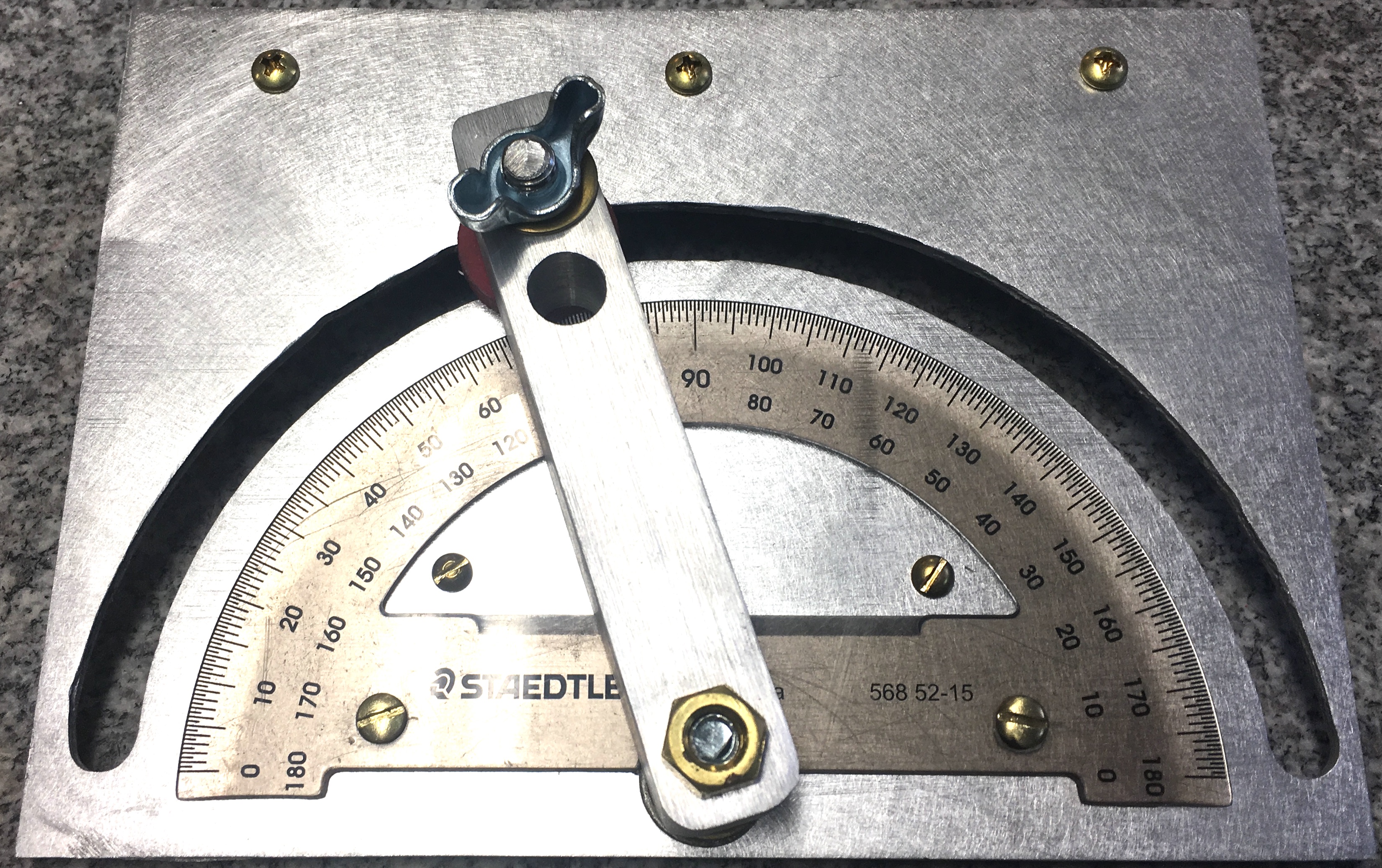

For a while now Ive wanted to have a way to sharpen my metal lathe cutting tools. In particular the angles must be precise for best cutting action. The top surface of the tool is often ignored but its as important as the faces.