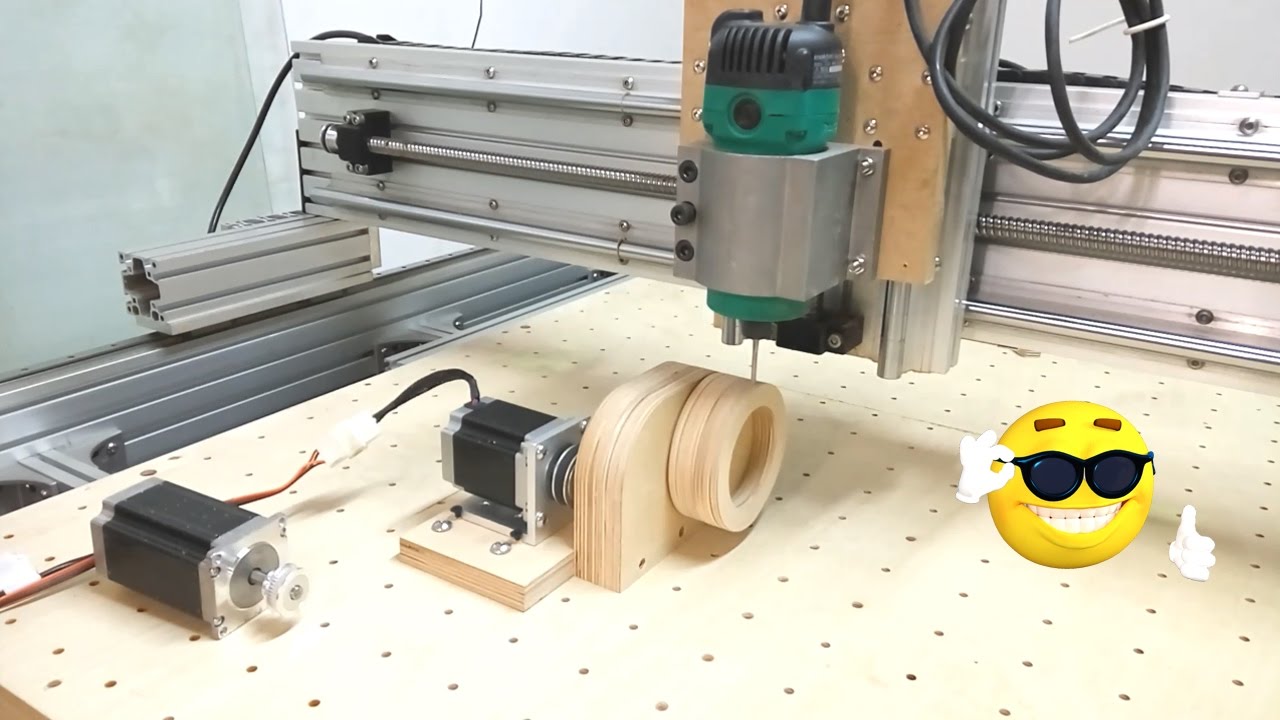

How To Make Lathe Chuck

Carefully cutting out the main part on the bandsaw.

How to make lathe chuck. Of course if you have a CNC metal lathe the whole. To index the mini chuck so that the slots for the jaws will be at 90 deg I put a brass plug in the chuck blank then screwed in some long 10-32 cap. Just as with the four-jaw chuck screw attachment to attach wood to a lathe using the dedicated screw chuck be sure to seat the blank all the way down to the base for a secure attachment.

Mill out a bevel and tip on the leading edge of the jaws. I used my BigPrint program to print a 11 template of the main part of the chuck and cut it out of Baltic birch plywood. Once the faceplate is attached to the disks put it on your lathe and turn the disks perfectly round removing as little wood as possible to maximize the size of the chuck.

Use light cuts at end about 0010. Now its time to mount your chuck to the lathe after mounting and removing the bowl from the lathe. Mill out the steps on the top side of the jaws.

Making a metal lathe chuck can be a little time-consuming but it is a valuable tool and the steps necessary to make one are useful primers on various machine-shop techniques. If you used a blank to test now make a matching set of four jaws. Screw the studs into the threaded holes and mount the chuck on the lathe.

In either configuration if the blank does not seat at the base of the screw chuck it can wobble or work loose and potentially go flying. One for the 3 jaw and one for the 4 jaw. Making the four jaw chuck.

Then bring up the tail stock to mark the true center. Adjust as needed small cuts. Also you must bowl tenon to the chuck and sand interior of the bowl.