How To Make A Parting Tool Holder

If superior tool edge sharpness is not necessary choose a 3-edge or 2-edge insert for a more economical solution or for larger diameters.

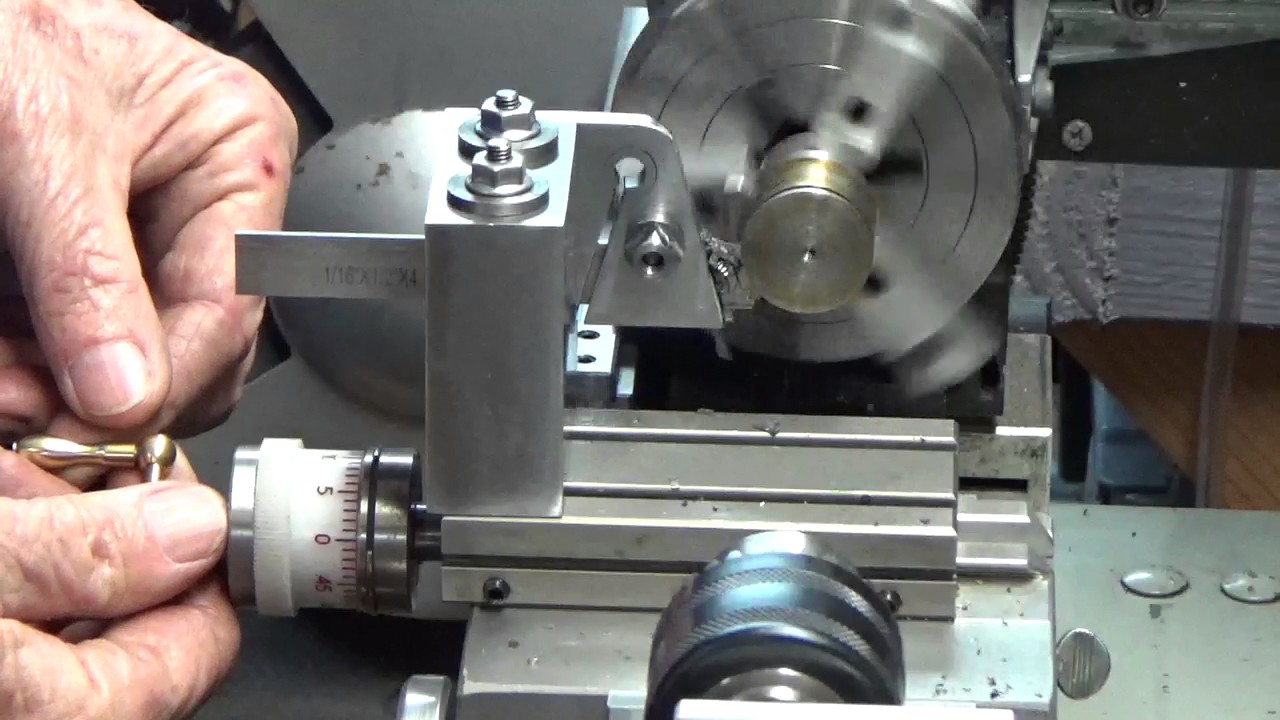

How to make a parting tool holder. To ensure the parting tool is perpendicular to the face of the chuck you can use a 1-2-3 block whose surfaces are ground to be parallel to one another. Back view showing how its mounted to the tool holder. How to Make a Parting Tool From A Sawzall Blade.

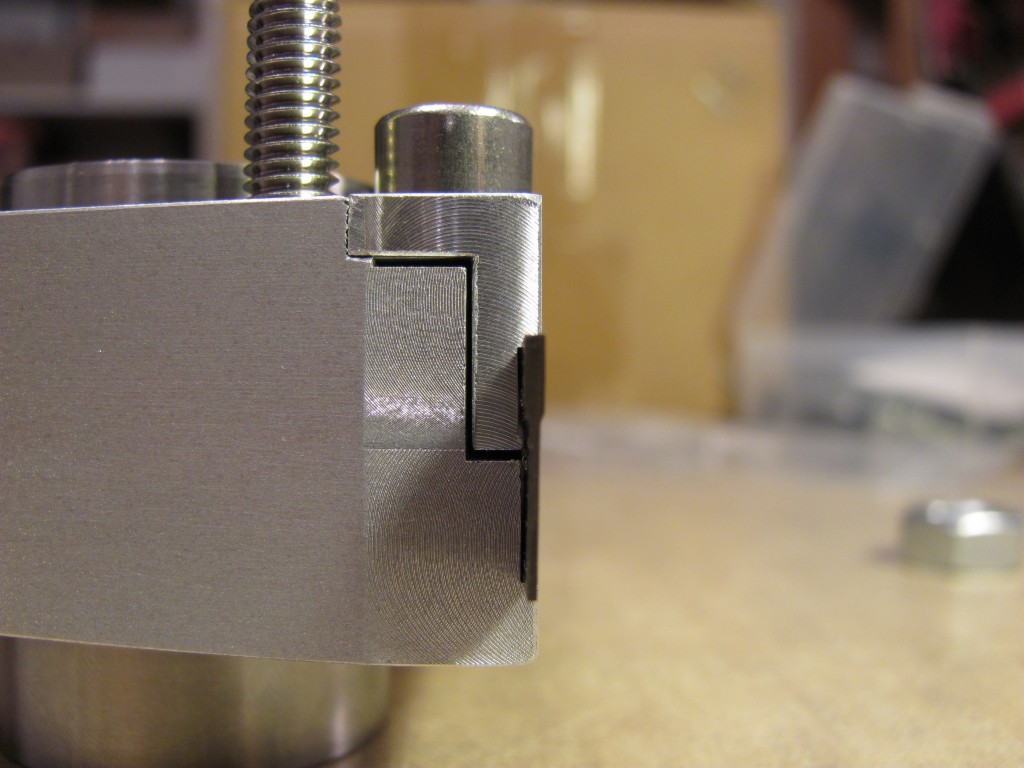

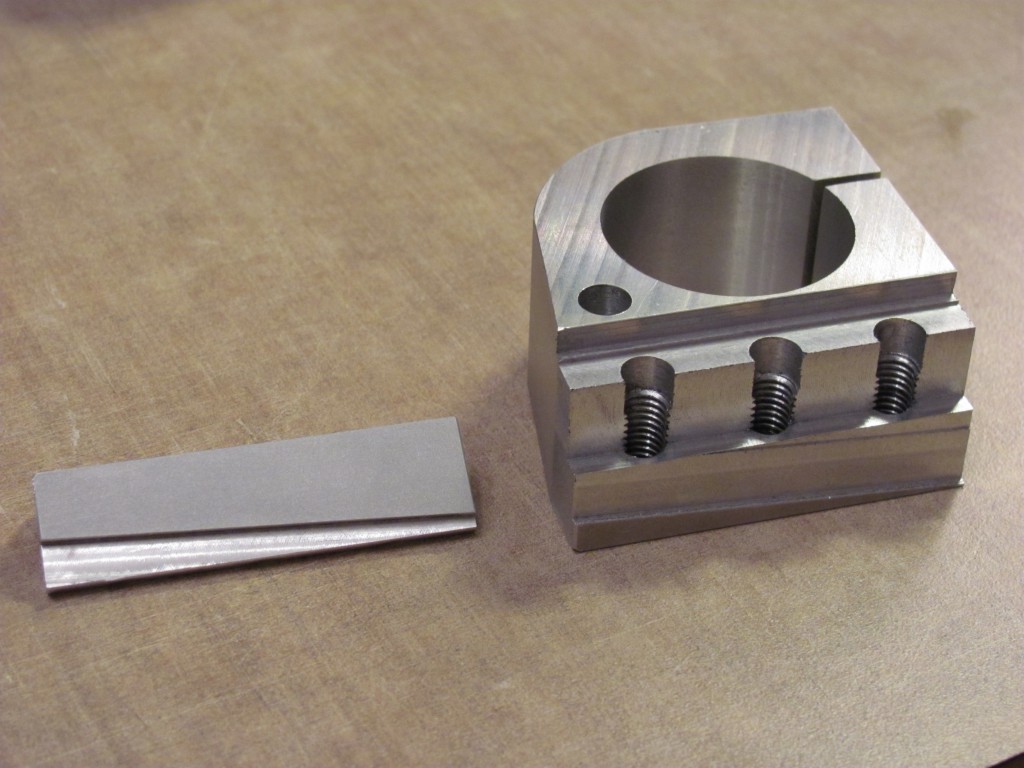

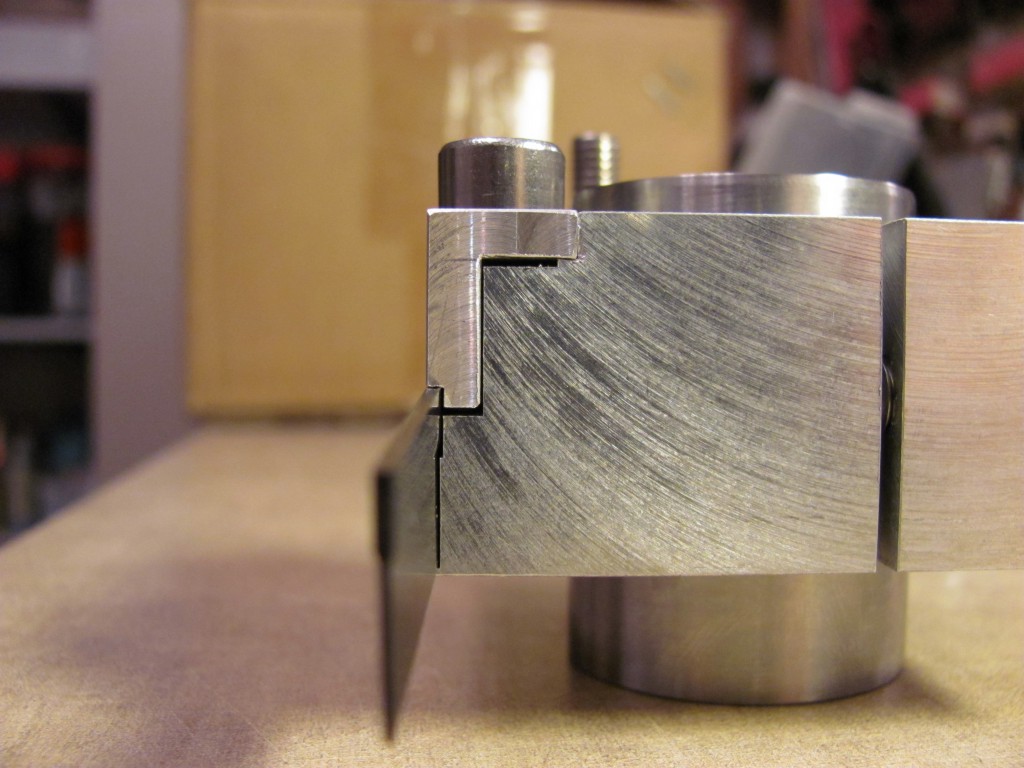

For 1 long try the front wedge for a sliding fit. The blade holder and a bar I milled and drilled and tapped 14-20 to bolt to the blade holder. Fig cranked parting tool holder.

I needed a parting tool that would give a little so I based my design on designs I found on the internet. Use a master square to set the tool holder square with the lathe chuck and tighten the nut to lock the tool holder in place. No matter what holder I make it still has to be adjustable so I could center the blade.

Repeat for 2 of the other sides. Cut the slot then remove the shims and enlarge the slot. Open out to 1 dia.

I had a short production run I needed to finish and part of the process required a small groove at the end of the piece. Meet Staffan and Johan the brains behind the new ingenious way of parting along the Y-axis which challenges conventional machining. Leave one side with no slot.

Its made from scrap. With our cutting tools for parting and grooving you get high productivity and long tool life helping you deliver plenty of components out of the workshop door. The problem of snatching with HSS parting blades.