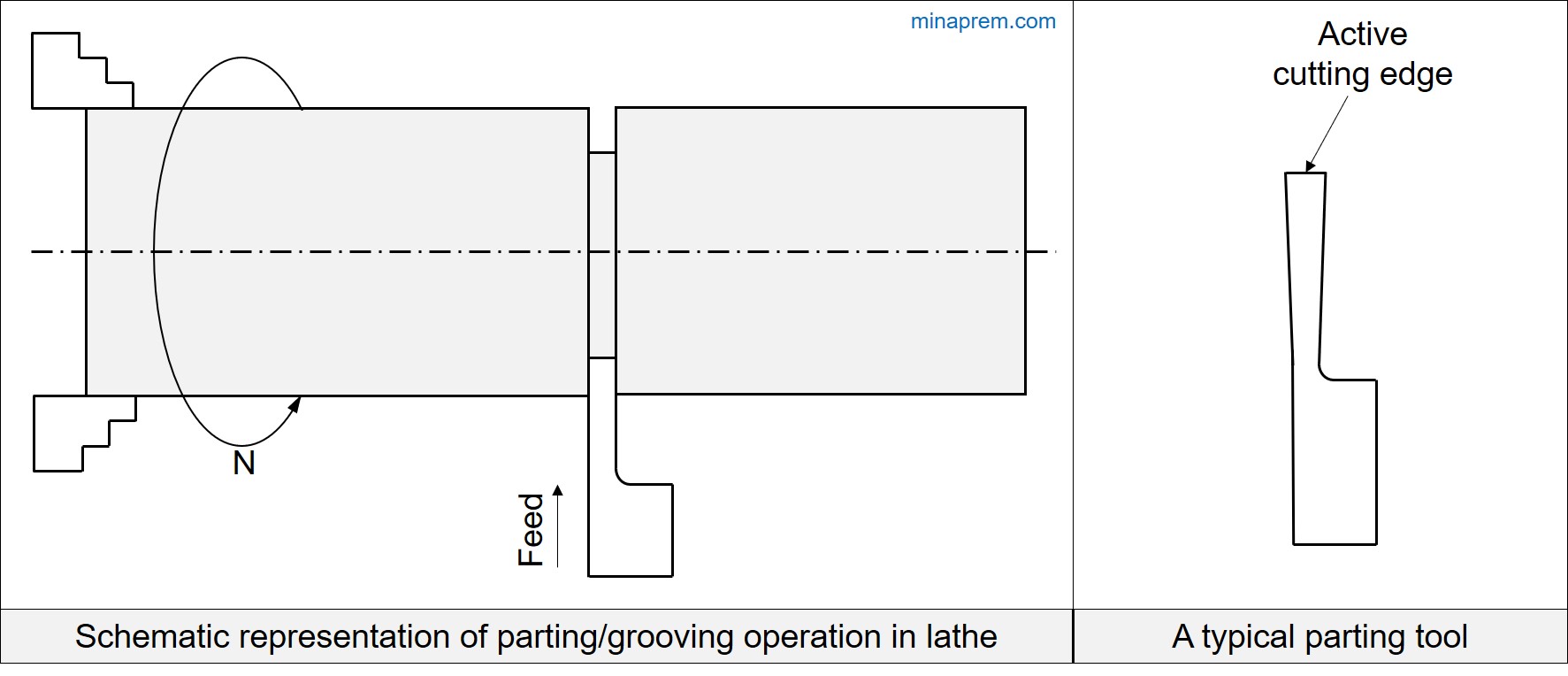

How To Grind A Lathe Parting Tool

Turn the grinder on and lower the tip of the parting tool onto the moving grinding wheel for a few seconds.

How to grind a lathe parting tool. Sharpen square- or round-nose scrapers on a bench grinder. When ground flat on the platform not vertical it will have a flat edge rather than a hollow-grind. Next I took the blade over to the disk sander and ground it down to bare metal.

I intend mostly to use them for roughing and for preliminary grinding of reliefs on drills. In this example we are making a normal right handed tool for the lathe. You can apply a degree of back rake at the same time too if you desire.

Being excited I went to the wood lathe to try out the new parting tool. Grinding down too far will have the effect of reducing the blade width and so limits the depth the tool can be plunged. You can see that Ive got a ways to go yet.

To use the blade needs grinding back on the top surface for as long as you desire in front of the clamping area removing the top surface to below the bevel. You can use whatever back rake you like if you achieve it by angling the entire blade like the Aloris holder. Edges faceedge need to be 90 so must be held square to wheel.

1 Its difficult to sharpen the bevels of a parting tool and arrive at the correct side profile with the ears leading the nose. I shaped the end of the blade like the Sorby Parting Tool double angle look. Im assuming youre talking about your average HSS parting blade including P-type If you grind the top of the blade the tip becomes lower than the original top.

To be clear the back rake angle on the P-parallel bits is best controlled by the choice of tool holder. Another thought on parting is to try to do your parting as close to the chuck jaws as possible. I was working on a handle for a gouge blade.