How To Do A Wood Framing Takeoff

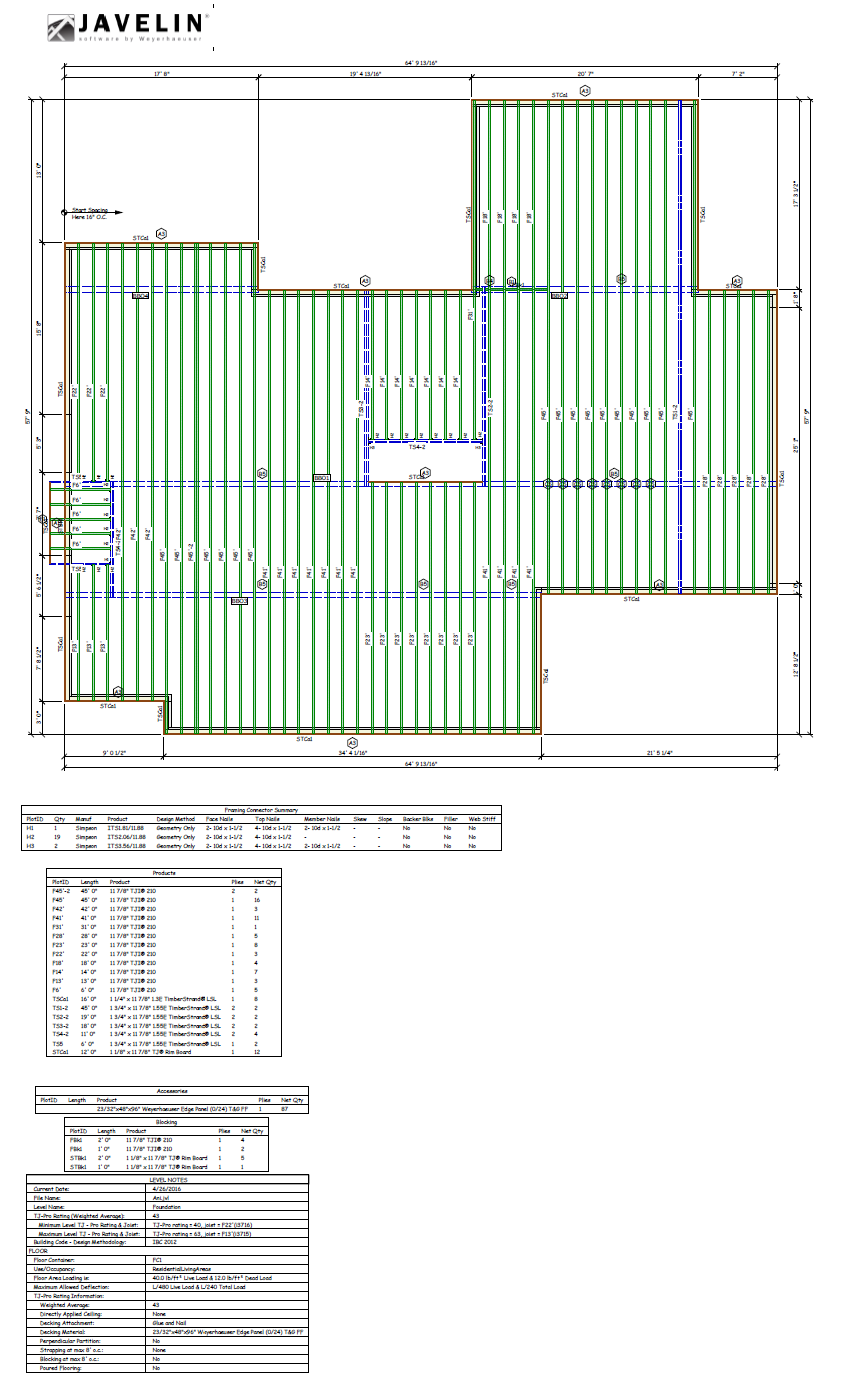

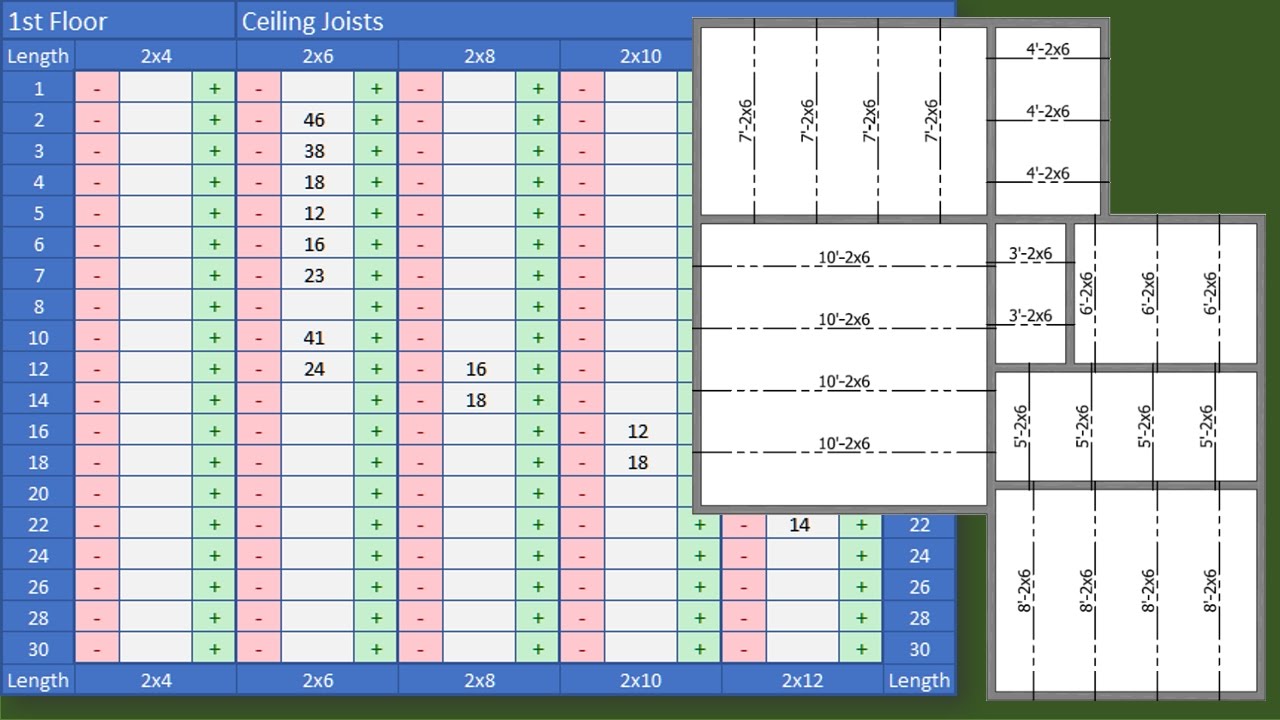

We organize the takeoff by grouping each species of wood together and listing them by size.

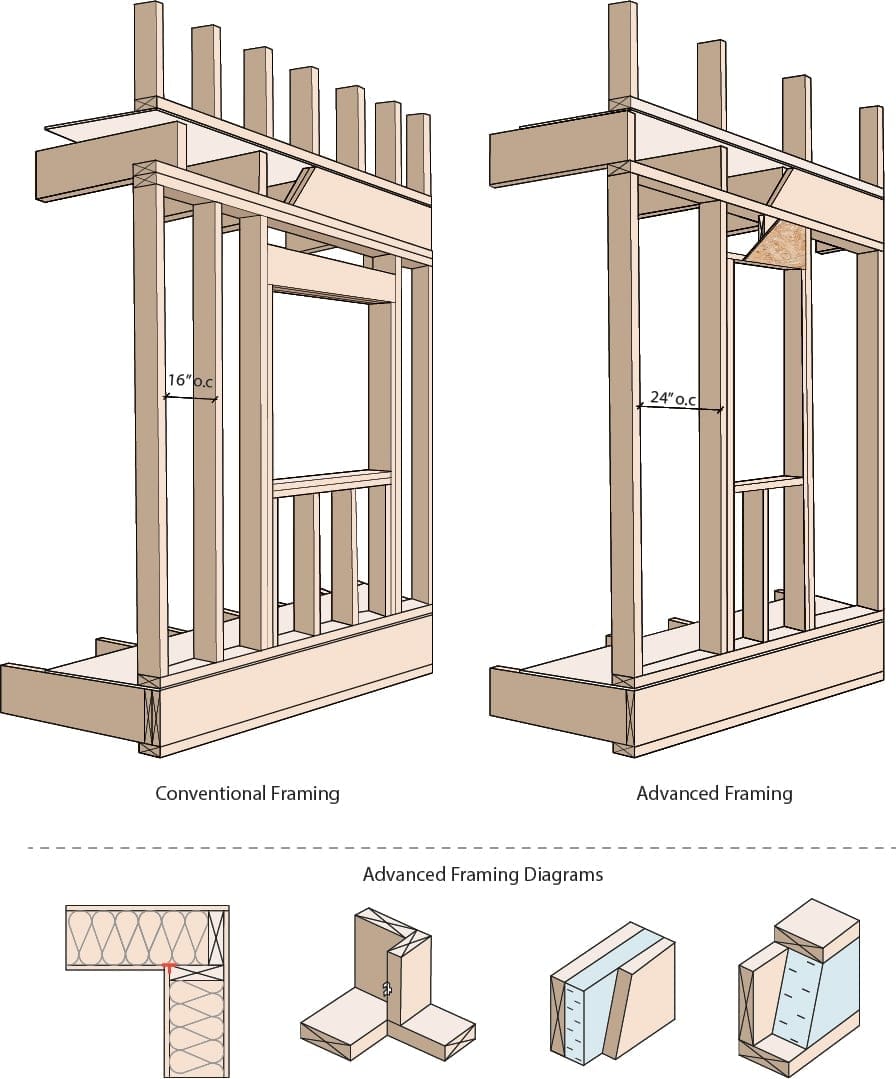

How to do a wood framing takeoff. Taking exact measurements and adding in a set percentage for wastage will create a consistent cost-scale that you can be confident in. Lets review the lumber framing trade the wood estimating process and also how Rocket Takeoff. We go over the stu.

If you want to play along do a quick lumber takeoff on this plan. To use a Takeoff Assembly. Takeoff in construction or material takeoff MTO is an essential part of the estimating process.

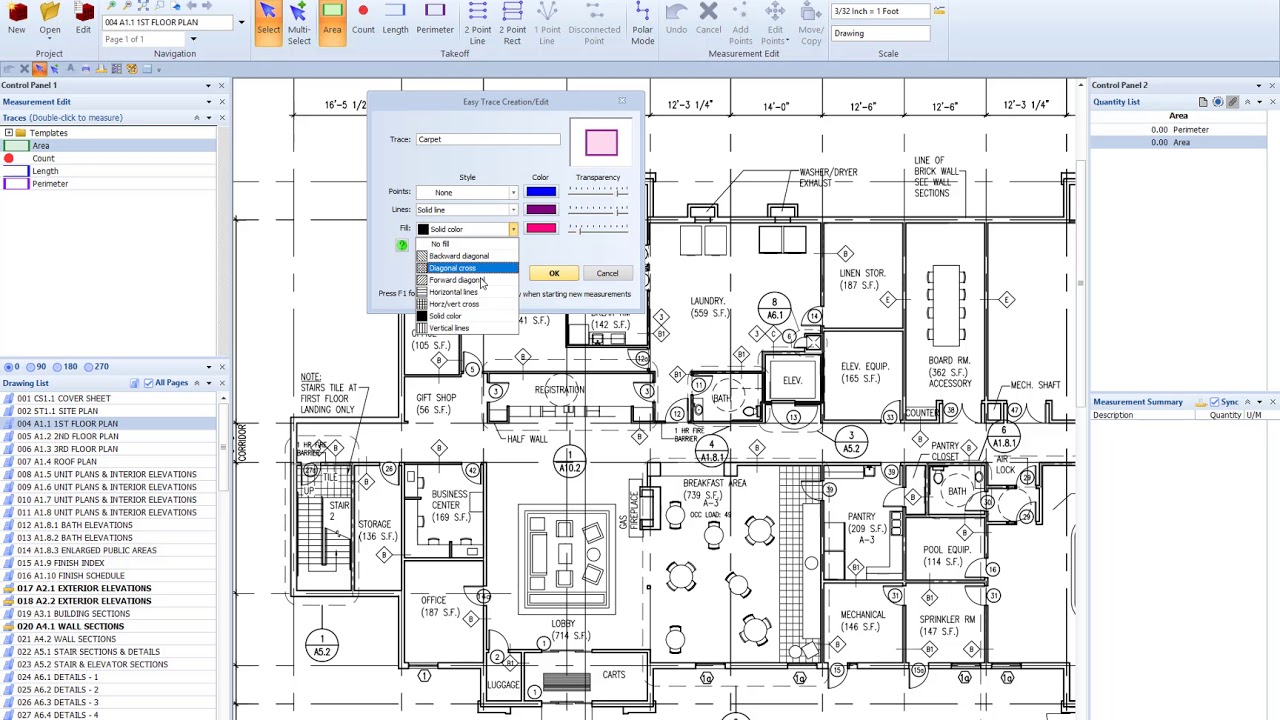

Our wood-plastic composites estimating services are reliable and accurate. The templates provided by PlanSwift are examples but you can create your own using the templates tab. Lumber Estimators we offer lumber framing takeoff services and cost estimation services.

Then Square Takeoff is the solution for you. Doing it by hand can also lead to accuracy errors. Our takeoffs include necessary sheathing construction hardware prefabricated shear walls and shear hardware framing and sheathing fasteners house wrap and flashing tape and adhesives to create the rough frame of the structure.

Below are the major steps that we follow to prepare a typical lumber framing estimate. Our drywall and framing takeoff software makes it easy for you to compute the number of man hours needed for a project and the number of materials such as studs tracks drywall insulation screws mud and others that may be needed for the project. Lumber takeoff and paint cost estimation.

Before an estimator can bid for a project they need to know the types and quantities of materials. From this the estimator can begin building a list of materials. Sorry if I dont understand what youve said lol.

/DoorFraming-238545a65b1a471a9588f5dfa18904af.jpg)

/WindowHeader-6c9fd92b5a6e49ef999cf4967beed3a5.jpg)