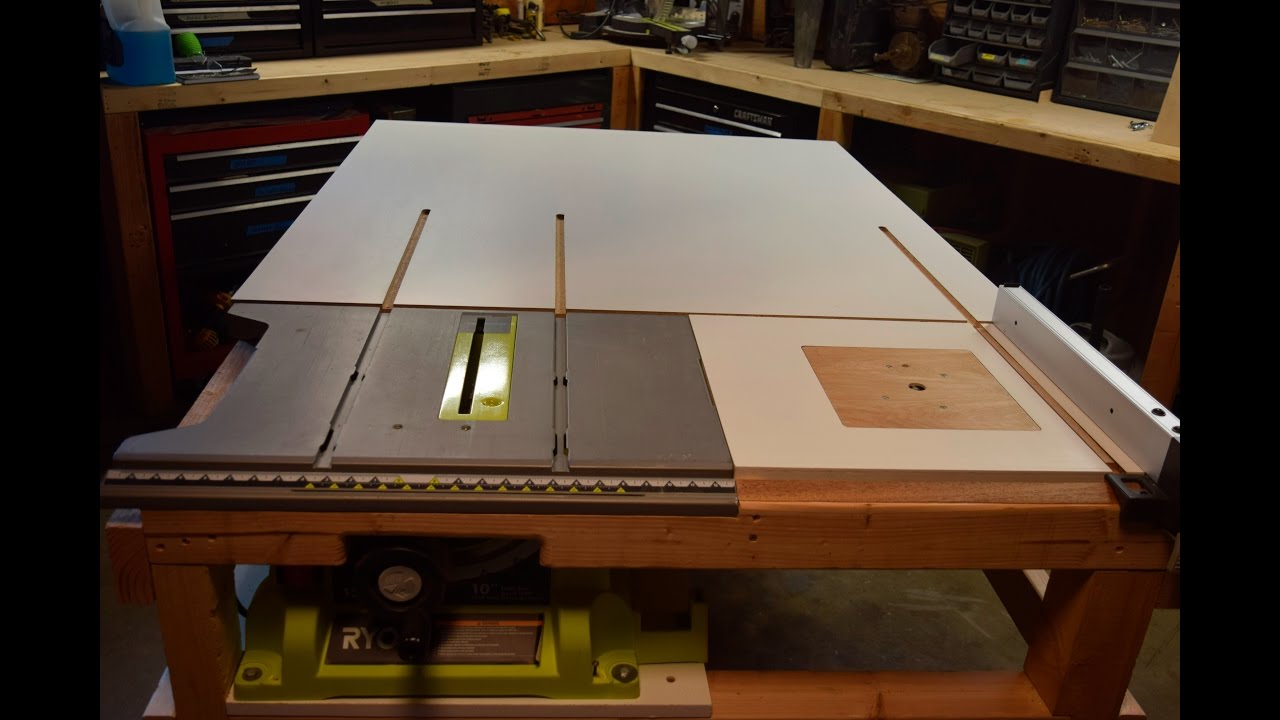

How To Build A Homemade Table Saw

But sometimes you need to make a new table saw fence when your old one doesnt work properly.

How to build a homemade table saw. I also had to make sure I could still get the saw out without disassembling the bracket. The table is marked for precise 225 45 and 90 degrees. I also have a sheet of 12 plastic that will be used for the trunnions and top.

At beginning idea was to make a modular system but in process I changed. Maximum width of material for cutting at 45 degree is 11. Basically it comes up with a table saw.

You would find all the necessary materials listed in the written version of the tutorial. Clamp the saw to the aluminum angle so its flush with both door bottoms. In this video I show how I made a decent table saw with good fence and miter gauge.

Add a couple of hinges for fold-up storage and youre ready to rip. Wood screws 50mm and 16mm with flat head. Very accurate cuts are easily made.

The fence for the sliding table pivots on a point and clamps to the edge to set it for any angle. You get three instruction methods in one so you dont have any excuse for not building your table saw stand. SHAFIRE Electric Drill Cutting Seat Stand Support Angle Grinder 2 Wrench 2 Gasket - BlackhttpswwwamazonindpB07H89WKH6refcm_sw_r_cp_apa_glt_fabc_AMCK.

In this video Ill show you how to make a homemade table saw using a circular sawFor various woodworking projects I found that circular saw isnt enough for. The table saw fence is an important part of a table saw. Otherwise I wouldnt be able to get it back in once its glued together.